| Packing AlNiCo | |

|

Preferred Method I like to see drivers arrive at there destination unscathed by the rigors of transportation. This method was developed as a figured out the quickest & most consistently bulletproof way to package up vintage speakers. I have now shipped in the thousands of drivers with only 3 failures in shipping. Each and every one of these failures was due to "concussion" -- the shifting of the alnico slug from the package stopping abruptly after a fall. Since started to explicitly brace the maagnetic slug i have had no failures during transit. With the exception of bracing the magnet the same technique is used for packing most ceramic speakers too. My current technique has developed to be an amalgam of these 2 methods... the use of a separate material to brace the alnico slug -- as in the alternate method below -- has supplanted the use of the cardboard. |

|

|

|

|

|

The job at hand. |

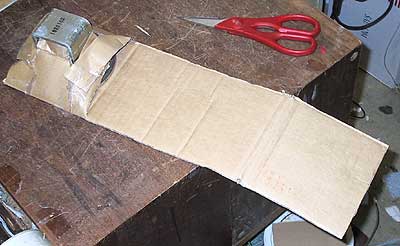

Cardboard cut to shape for sheath |

|

|

|

|

The 2 cardboard flaps are cut and positioned to support thecylindrical magnet slug (on rare occasions the slug can come loose if the box has a good fall -- without showing any damage to the box). |

One, |

|

|

|

|

Two, |

Three. |

|

|

|

|

A pair of drivers in their sheaths |

Drivers together face-to-face (this is a usually convienent option) |

|

|

|

|

Into a plastic bag. |

A pair of drivers ready to be packed into a box for shipping. Some crush space is left between this package and the outer box. Closed cel foam or packing peanuts. |

|

Alternate Method |

|

|

|

|

|

Same again but with an alternate magnet support technique. |

Appropriate width closed cel foam. |

|

|

|

|

wrapped around the magnet slug and taped down. |

The rest is essentially the same |

|

|

|

|

|

|